As 1000MW units become more common in China, the internal leakage problem of their accompanying minimum flow valves is also more prominent. To make matters worse, replacements offered by original equipment manufacturers are expensive, slow to deliver, and often sent without support personnel.Binda solves these problems by modifying these minimum flow valves. Borrowing from the experience of over 300 minimum flow valves produced, Binda produces a new valve trim to install into the original body. Imported minimum flow valves (CV, ABB, CCI) modified by Binda are able to meet or even exceed the performance of their original, unmodified counterparts. This high level of performance is guaranteed by Binda’s proprietary multi-stage vortex type throttling trim.

In May 2016, the modification of two minimum flow valves was complete for the 1x1000MW unit at Wanneng Tongling Power Plant.

Modification details is explained below.

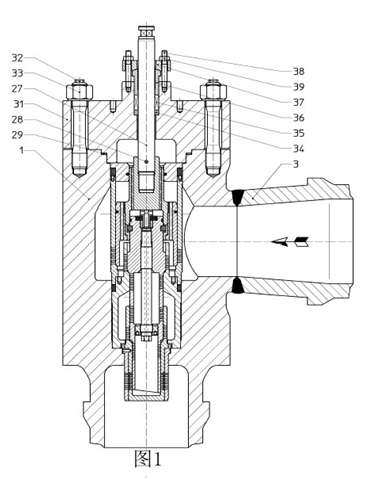

Original CV valve section view

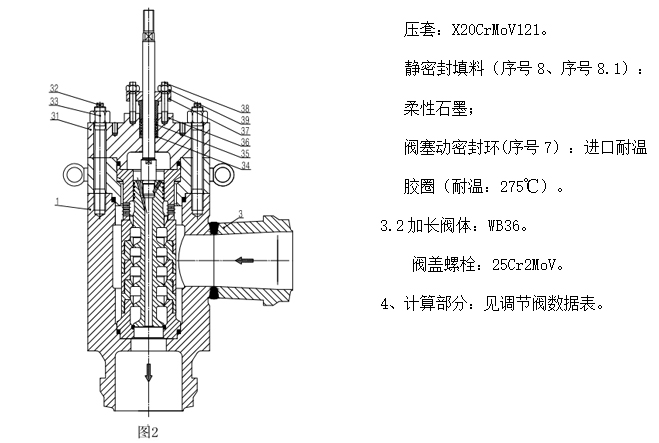

Modified CV valve section view

Modification details:

1. The original valve body, bonnet, and actuator are retained. Only the valve trim is replaced.

2. The valve trim is removed, and Binda’s proprietary valve trim is installed into the valve.

3. Binda’s valve trim is of the axial flow type, with numerous throttling stages. This necessitates an increase in the axial length of the valve body. An extension to the valve body is installed.

4. The bonnet bolts are replaced with the appropriate type.

5. The actuator and accessories are re-installed.

Proprietary valve trim features:

The proprietary valve trim is the world’s first multi-stage soft sealed valve trim, significantly improving the trim’s resistance to erosion.

Note:

1. The proprietary valve trim has 8 throttling stages. The first stage is a fixed area drilled disk, and the second a pair of rigid sealing surfaces hardfaced with stellite. Subsequent stages are variable area, anti-cavitation soft seal stages.

2. At the last six stages (from 3rd to 8th), Binda’s proprietary soft seals are used. (See figure below) When the valve stem is in the closed position, the soft seals are closely mated with the valve plug, cutting off the leak path of the medium. This significantly reduces the pressure drop at the rigid sealing surfaces, increasing their lifespan.

3. Strength guarantee: the strength of replacement parts are guaranteed to match their original counterparts. The safety of the modified valve is unchanged.

4. Flow characteristics: Binda possesses its own hydrodynamic laboratory. The modified trim is thoroughly tested to ensure the flow of the new design meets specifications. This quantitative approach provides accurate real-world data.

5. Soft seal rings are constructed from premium materials to ensure performance under harsh conditions.

6. Quality guarantee: no leak within 4 years

7. Modification time: 15 to 20 days.

Installation environment

Before

After